Passion through the generations

In Sykkylven, new generations stand on the shoulders of their ancestors and take pride in creating extraordinary furniture for quality-conscious customers. The production process follows strict guidelines, and the quality control is extensive.

Working together

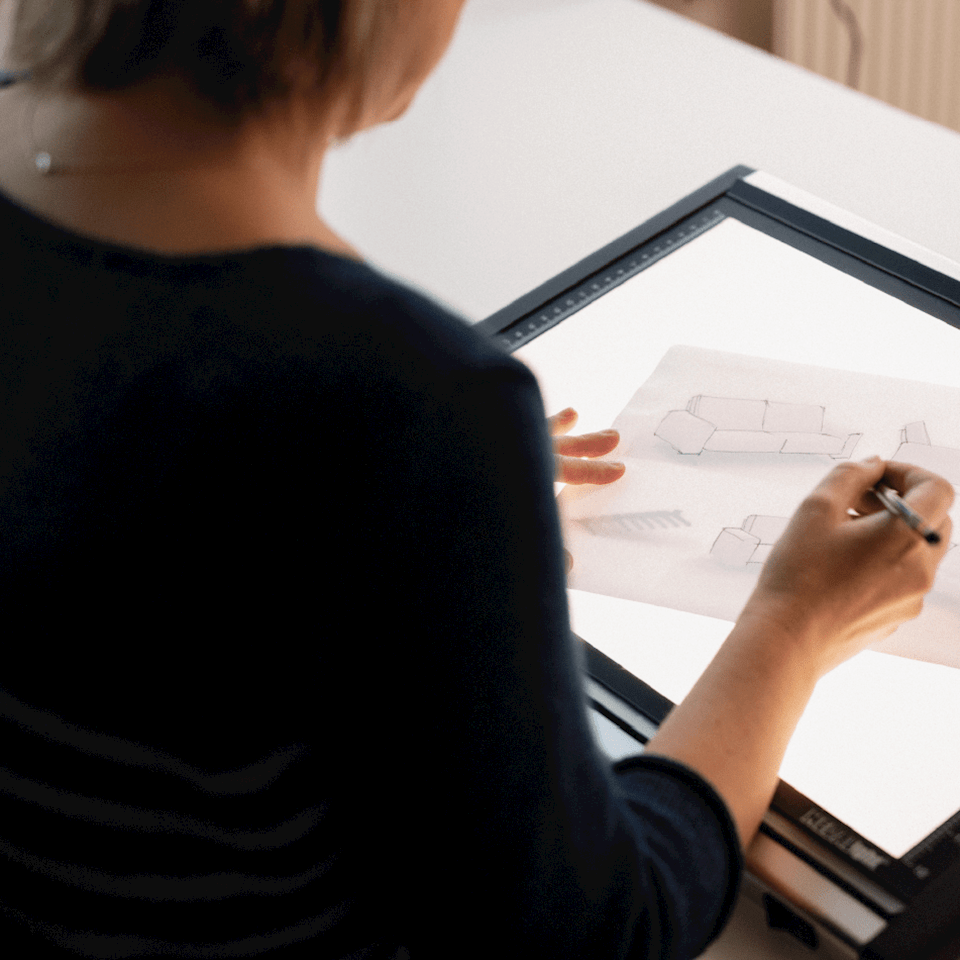

Designers, engineers, specialists in woodworking, steel, and foam, seamstresses and upholsterers work side by side with advanced machines and robots. The entire production line is filled with accomplished craftsmanship that goes hand in hand with modern technology. In Sykkylven, skills and a sense of quality merge together with our raw materials and the surrounding nature to form a unified whole. You can both see and feel that Stressless® recliners, for the most part, are still being produced and assembled by hand.

Norwegian design50 years of passion

Skills are passed on with pride and passion, and with the conviction that strives for the best. Working at Stressless® is not just a job; it is about being part of a culture that has been built over five decades. It is about teamwork, connections between people, nature and forward thinking.

Attention to detail

From the beginning of the design process and the development of 3D-printed components and prototypes through to the final production: every little screw, milling, assembly and sewing detail is important for a premium product. A microscopic notch in the wood, irregularities in the leather, a weakness in the steel frame – nothing escapes the gaze of our quality controllers.

Making it better

Under the surface of supple leather and cozy fabric lies true engineering genius. From multifaceted sets of springs to foam that contours to your body, every aspect that goes into a piece of Stressless furniture is deliberately assembled to bring you an unparalleled seating experience. Understanding the science of comfort and movement fueled our innovative spirit and desire to design the most comfortable, unique furniture in the world.